Cut thickness - Specify the thickness of the cutter utilized for cutting the material.

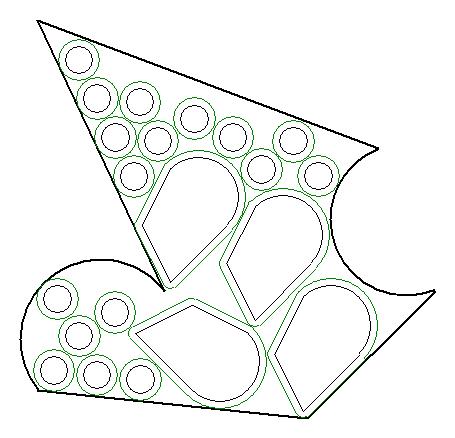

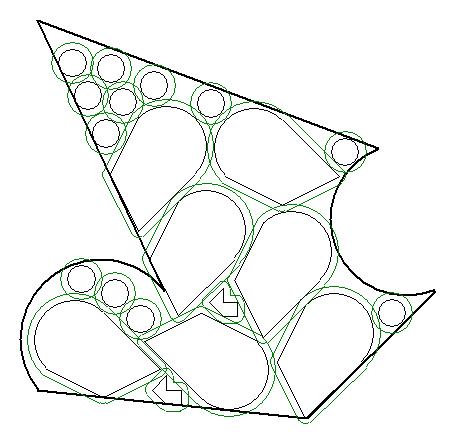

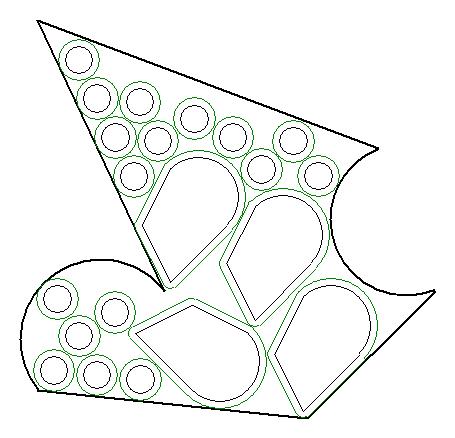

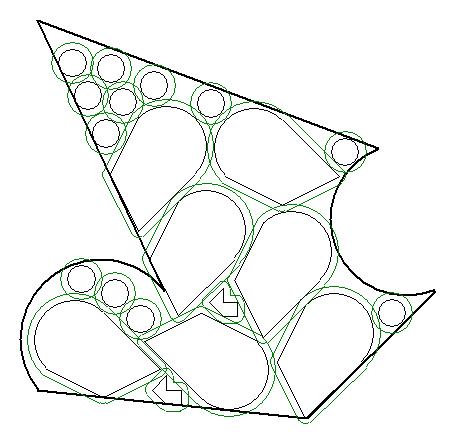

Resolution - The parts and stock pieces are not utilized in optimization at their true-shape. They are approximated using a resolution. Increasing the resolution (by decreasing the value of this property) will lead to a larger running time. This is one of the main factors which influence the speed of the optimization.

Precision - A value used for deciding if 2 real numbers are equals or not. Make sure that this value is much smaller than the size of pieces. A good value is 10-6 unless your pieces are closer in size to this value.

Overlap cuts - Specify if the cuts overlap or not. Possible values are:

Allow part in part - specifies whether a part can be placed inside the hole of another part.

Starting corner - Specifies the corner from which the placement of parts is started. Possible values are:

Starting direction - Specifies the direction in which the placement of parts is started. Possible values are:

Cut thickness - The thickness of the cutter utilized for cutting the material.

Minimal break size - Waste smaller than this value cannot be generated because the material will break. Set it to 0 if the material does not break.

Fractional values must be rounded to: - If you work with fractional values (e.g. 15 1/8) they will be rounded to this value.

Maximal cut length - A cut cannot be longer than this value.

Minimal useful size - Waste smaller than this value will not be added to Stock when the Accept button is pressed.

Waste type - Specifies how the waste should be generated. Possible values are:

Optimization type - Specify how cuts are performed. Possible values are:

Cut thickness - The cutting blade width for 1D (linear) materials such as pipes, bars, etc.

Minimal usefull size - The pieces having the size less than this value will not be inserted in the REPOSITORY.

Max pieces per bar - The maximum number of that can be cut from a bar.

Limits for waste - Waste can be either greater than a value or smaller than value. Waste cannot be between those 2 values.

What to minimize - Total waste or total price.

Maximul distance between 2 linked segments - DXF files contain multiple distinct entities (lines, polylines, arcs, etc). These entities must be linked together in order to form a closed shape. Not in all cases the end position for an entity is the start position for another entity. There may be some gap between them. This property specify the distance required for linking consecutive entities. It must be greater than 0 in order to be sure that the entities are linked continuously.

Consider entities from all layers - All shapes from all DXF layers are taken into account.

Optimization level - Controls the speed and the quality of the optimization. Increasing the Optimization level will lead to better results, but they are obtained in a longer time.

Fractional values must be rounded to: - If you work with fractional values (e.g. 15 1/8) they will be rounded to this value. This applies to linear and rectangular cases only!

Price per what - The price column from Stock table contains prices per entire sheet or only per unit of material.

Number of parallel computations - Specify how many computations can be performed in parallel. Higher values are better. This number should not exceed the number of cores of your processor. This value applies to Polygons and circles optimization only.